In what situations would you choose U-shaped screws over alternative fastening methods?

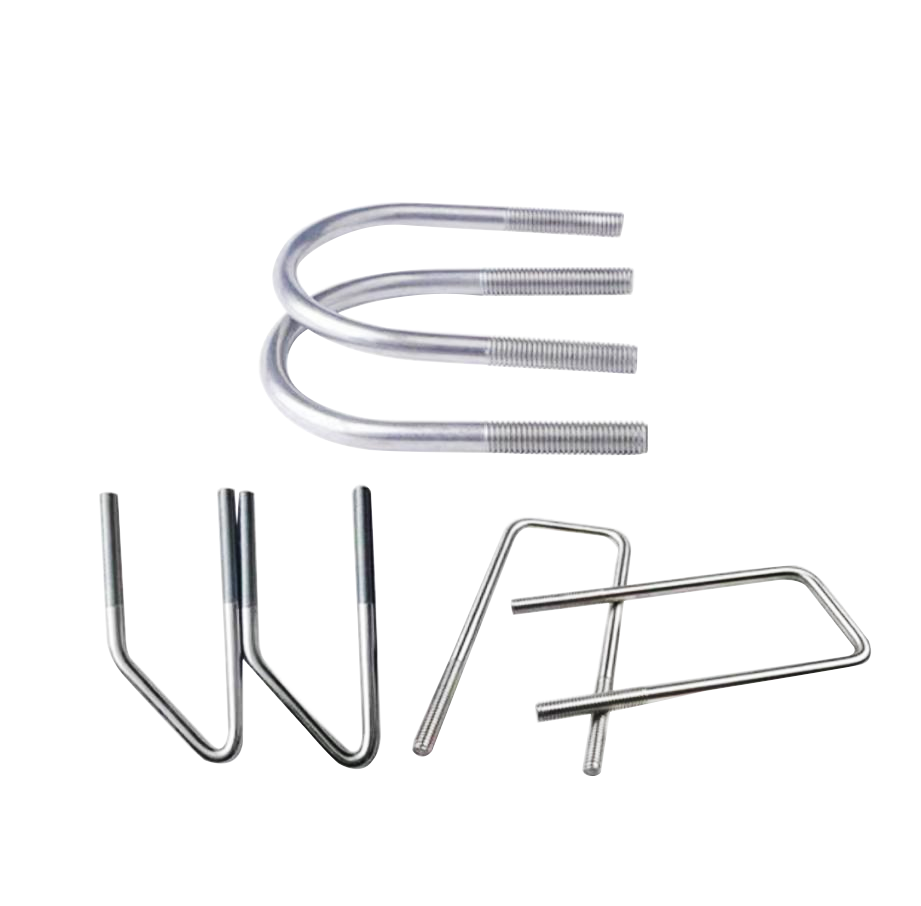

In the realm of fasteners, the humble U-shaped screw, or U-bolt, stands out as a versatile and reliable solution for a multitude of applications. From securing pipes in plumbing systems to anchoring heavy machinery in industrial settings, U-shaped screws offer distinct advantages over alternative fastening methods.

Securing Cylindrical Objects with Precision:

U-shaped screws excel at securing objects to cylindrical structures such as pipes, poles, or beams. Their unique design allows them to wrap around the object securely, providing a robust grip. When precise alignment or positioning is crucial, the adjustable nature of U-shaped screws, facilitated by their threaded ends, proves invaluable.

Versatility Across Industries:

One of the standout features of U-shaped screws is their versatility. They find application across diverse industries, including automotive, construction, plumbing, and beyond. Whether it's fastening components in a vehicle's chassis, attaching scaffolding on a construction site, or securing pipes in a plumbing system, U-shaped screws offer a dependable solution.

Effective Load Distribution:

The U-shaped design of these screws plays a vital role in distributing loads evenly across the object being secured. This feature is particularly beneficial in situations where there is significant stress or vibration. By reducing the risk of concentrated pressure points, U-shaped screws contribute to enhanced stability and longevity of the fastened components.

Resilience Against Shear Forces:

U-shaped screws are adept at resisting shear forces, making them suitable for applications where the fastener may experience lateral or sideways pressure. This quality makes them ideal for securing objects in environments where movement or external forces are prevalent.

Accessibility and Ease of Installation:

In addition to their functional advantages, U-shaped screws offer practical benefits in terms of accessibility and ease of installation. Their design allows for straightforward installation and removal, even in tight or hard-to-reach spaces. This accessibility simplifies maintenance tasks and reduces downtime in various applications.

Corrosion Resistance for Harsh Environments:

Depending on the material chosen, such as stainless steel or galvanized steel, U-shaped screws can provide excellent corrosion resistance. This feature is particularly crucial for outdoor or harsh environments where exposure to moisture, chemicals, or extreme weather conditions is a concern. The corrosion resistance ensures longevity and reliability, even in challenging conditions.

The decision to choose U-shaped screws over alternative fastening methods hinges on their unique combination of versatility, precision, load distribution, resilience, accessibility, and corrosion resistance. Whether it's securing objects to cylindrical structures, distributing loads effectively, or withstanding harsh environmental conditions, U-shaped screws emerge as a dependable and practical choice for various fastening needs across industries.

Related products

-

Round Head Cross Self-Tapping Screw

-

Cross Flat Head Dry Wall Nail

-

Hexagonal Cement Nail In Plum Blossom Groove

-

Large Flat Head Plum Blossom Groove Grass Rope Nail

-

Grade 8.8 Outer Hexagonal Bolt

-

304 Stainless Steel Teeth

-

304 Stainless Steel U-Shaped Screw

-

304 Stainless Steel Hex Nut

-

Iron Galvanized Flange Nut Hexagonal Anti Slip Locking Belt Tooth Washer Screw Cap

-

Stainless Steel Outer Hexagonal Bolt

-

Stainless Steel Countersunk Head Self-Tapping Screw

-

Stainless Steel Pan Head Drill Tail Screw

English

English  English

English 中文简体

中文简体 русский

русский