The Risks of Using Substandard Screws: Why Certified 8.8 Grade Fasteners Matter

Using substandard screws instead of certified 8.8 grade fasteners can pose significant risks across various applications, particularly in construction and heavy machinery. The 8.8 grade designation indicates a minimum tensile strength of 800 MPa, which is crucial for applications that endure substantial loads and stress. Substandard screws, lacking proper material integrity and strength specifications, may fail under similar conditions, leading to structural failures, equipment malfunctions, and potential safety hazards. This is especially critical in environments where the stakes are high, such as construction sites or industrial settings, where the integrity of machinery and structures directly impacts human safety and operational efficiency.

When substandard screws are employed, the consequences can be dire. A failure of these screws can result in catastrophic events, including equipment breakdowns or even accidents that cause injury or loss of life. Additionally, the economic implications can be severe; replacing damaged components, addressing safety violations, and managing downtime can lead to significant financial losses. The initial savings from choosing cheaper, non-certified fasteners can quickly evaporate, making it an ultimately costly decision. Moreover, substandard screws may not provide the reliable fastening necessary to withstand vibrations and environmental stressors, leading to premature loosening and further compromising structural integrity.

Historically, the development of high-strength fasteners like the 8.8 grade has evolved in response to the demands of increasingly complex engineering challenges. The engineering community recognizes that investing in quality fasteners is crucial for the longevity and safety of construction projects. As such, using certified fasteners is not merely a matter of best practices but a necessary standard that underpins safe engineering and construction. By opting for high-quality, certified 8.8 grade screws, professionals can ensure that their projects meet safety regulations and performance expectations, ultimately safeguarding both their investments and the people who rely on their work. In conclusion, the risks associated with using substandard screws extend far beyond immediate cost savings, emphasizing the importance of adhering to quality standards in fastening solutions.

Related products

-

Pan Head Cross Series Drill Tail Screws

-

Round Head Huasi Cross Series Drill Tail Screws

-

Pan Head Cross Series

-

Countersunk Cross Shaped Fiberboard Nail

-

Cross Flat Head Dry Wall Nail

-

10.9 Grade Flange Outer Hexagonal Fine Thread Bolt

-

Grade 8.8 Outer Hexagonal Bolt

-

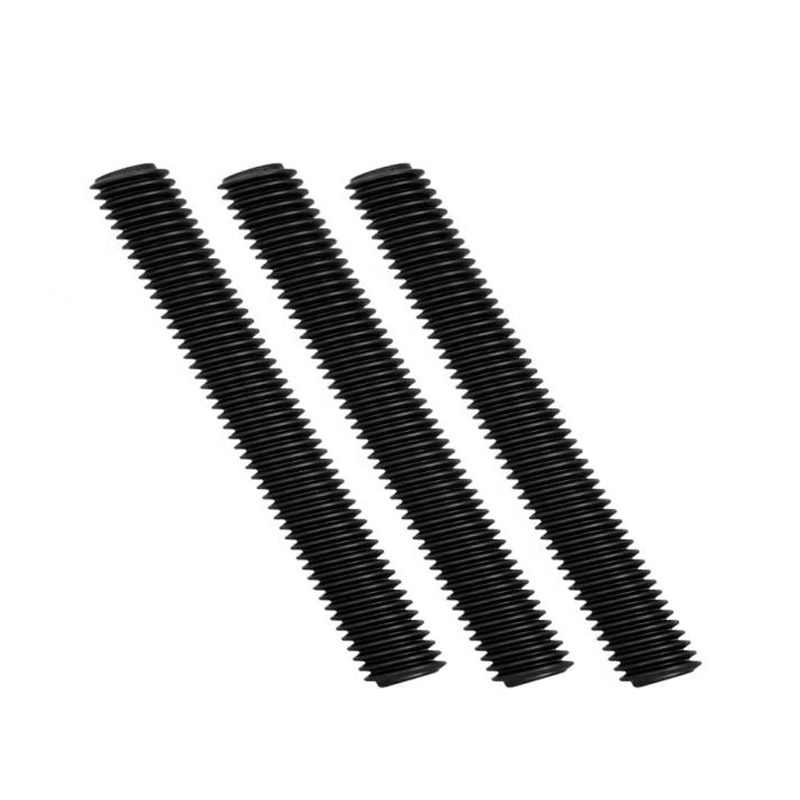

8.8 Grade Tooth Bar Full Teeth

-

Hexagonal Galvanized Nut

-

304 Stainless Steel Hex Nut

-

Pan Head Self-Tapping Screw

-

410 Stainless Steel Outer Hexagonal Drill Tail Screw

English

English  English

English 中文简体

中文简体 русский

русский