What are the common mistakes people make when using square clamp right-angle screws, and how can they be avoided?

Using square clamp right-angle screws can significantly enhance the strength and stability of joints in woodworking, cabinetry, and construction projects. These specialized fasteners are designed to create secure connections at 90-degree angles, making them ideal for applications where robust structural integrity is crucial. However, like any tool or fastening method, there are common mistakes that can compromise their effectiveness if not properly addressed.

One of the most frequent errors is incorrect placement of screws. When screws are positioned too close to the edge of the material or too far from the joint, the square clamp mechanism may not exert optimal clamping force. This can result in weaker joints that are prone to loosening over time. To avoid this, it's essential to follow manufacturer recommendations regarding the distance from the edge and between screws, ensuring the clamp mechanism can securely grip both components at the joint.

Another critical mistake is over- or under-tightening the screws. Over-tightening can strip the threads or cause the material to deform, weakening the joint rather than strengthening it. Conversely, under-tightening can lead to a loose connection that compromises stability. Using a torque driver or following recommended tightening guidelines helps achieve the right balance of clamping force without damaging the materials involved.

Choosing the correct screw size and type is also paramount. Using screws that are too short or thin may not provide sufficient clamping force or structural support for the joint. It's important to select screws that match the thickness and material of the components being joined, ensuring they penetrate fully into the receiving material without compromising its integrity.

Pre-drilling pilot holes before driving the screws is another crucial step that many overlook. Failure to pre-drill can cause wood or other materials to split, especially near the joint area where stress is concentrated. Pre-drilling ensures that screws can be inserted smoothly and securely, reducing the risk of damage and ensuring a stronger connection.

Ignoring manufacturer guidelines for installation and usage is a common pitfall. Each type of square clamp right-angle screw may have specific recommendations regarding installation depth, torque specifications, and load-bearing capacity. It's important to consult these guidelines to ensure optimal performance and longevity of the joints.

Advantages of square clamp right-angle screws include their ability to create strong and stable joints quickly and efficiently. Compared to traditional methods like brackets or nails, these screws provide a more secure connection at precise right angles, which is essential for maintaining structural integrity in various woodworking and construction applications. Their design simplifies the process of assembling cabinets, shelves, and other furniture pieces, ensuring that joints remain tight and durable over time.

While square clamp right-angle screws offer significant advantages in creating robust joints, avoiding common mistakes during their use is crucial for achieving optimal results. By paying attention to screw placement, tightening procedures, screw size selection, pre-drilling pilot holes, and adhering to manufacturer guidelines, craftsmen and builders can ensure that these fasteners enhance rather than compromise the integrity of their projects. This attention to detail not only improves the quality of the joints but also contributes to the overall longevity and reliability of the structures being constructed or assembled.

Related products

-

Hexagonal Nylon Head Series

-

Pan Head Cross Series Drill Tail Screws

-

Round Head Huasi Cross Series Drill Tail Screws

-

Cross Flat Head Dry Wall Nail

-

304 Stainless Steel Teeth

-

Square Clamp Right Angle Screw

-

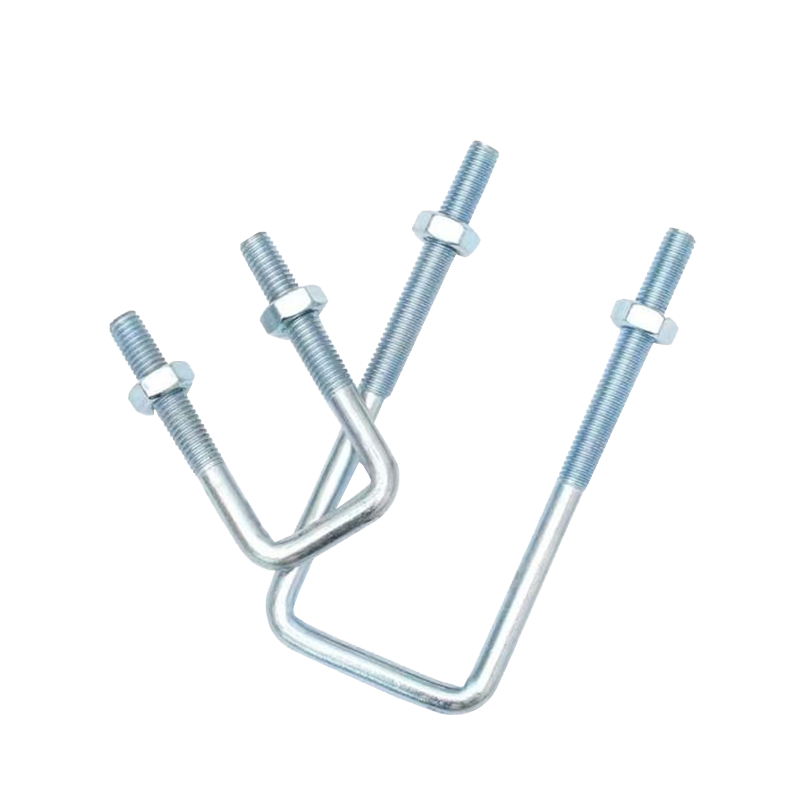

304 Stainless Steel U-Shaped Screw

-

Hexagon Weld Nuts

-

Stainless Steel Outer Hexagonal Bolt

-

Pan Head Self-Tapping Screw

-

Stainless Steel Pan Head Drill Tail Screw

-

Hexagonal Drill Tail Screw

English

English  English

English 中文简体

中文简体 русский

русский